Results

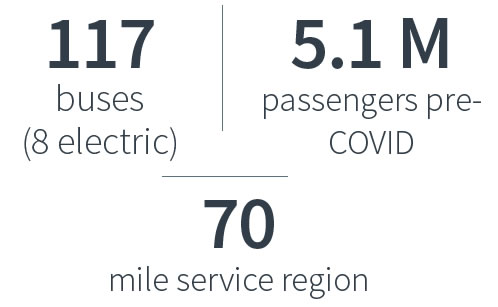

The final solution achieves RFTA’s goals of ensuring a consistent, automated process of meter and charging/fueling updates while leveraging a common set of EAM reports across their electric and diesel bus fleets.

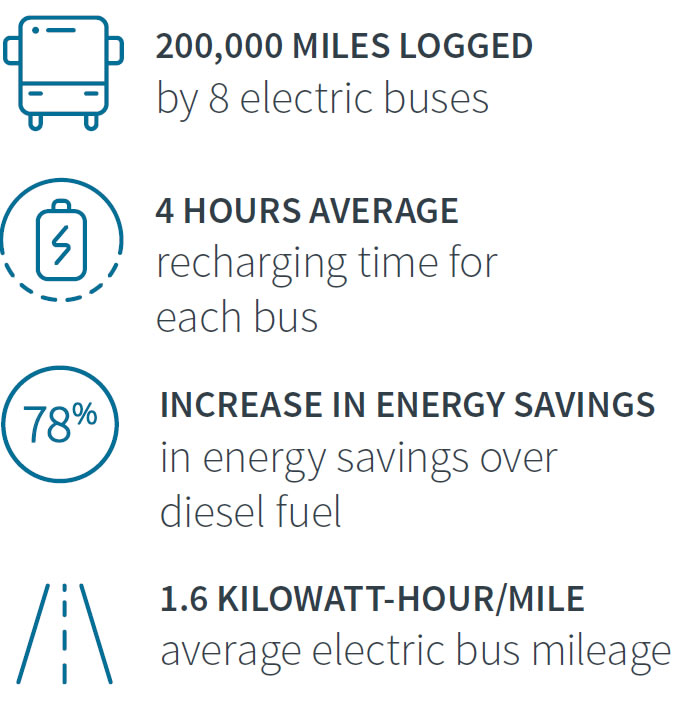

By tracking EV information in EAM, RFTA can now accurately measure charging events to track energy consumption and expenditure. RFTA is now able to quantify the following savings: it cost 18 cents per mile in fuel/propulsion for an electric bus compared to 82 cents per mile for diesel vehicles, a savings of 64 cents per mile. Analyzing the data gave RFTA valuable insights into bus electrification to inform its sustainability roadmap, data its board needed to justify expanding its electrification programs.

Another priority is evaluating battery health for performance assessment, to enable RFTA to analyze battery trends over time.

RFTA also learned valuable lessons from the integrations needed for the project. “Work on the integration ahead of time,” advised Danny Knight, RFTA’s EAM System Administrator. “Anything you can do upfront is ideal. Ensure that OEM and charger providers have the data available for integration. These are big steps to make your project go smoother.”

Next, RFTA plans to track fault codes to drive service requests and avoid larger issues, especially with regenerative braking, which drivers often turn off when going downhill on Aspen’s icy roads. RFTA is looking into getting fault codes into EAM to watch out for brake overheating when operators forget to turn regenerative braking back on. This will involve mapping fault codes into EAM’s telematics module, to trigger service requests and work orders.

For Danny Knight, the hard work on integrations and information tracking is paying off in meaningful ways.

“We’re saving a ton of money with propulsion, we’re cutting back on fossil fuels, and we’re really trying to align with our green initiatives. We’re feeling that it has been a success and we’re looking forward to what the future holds.”

Bus

Bus Rail

Rail Paratransit

Paratransit